共31章节616课时

共31章节616课时

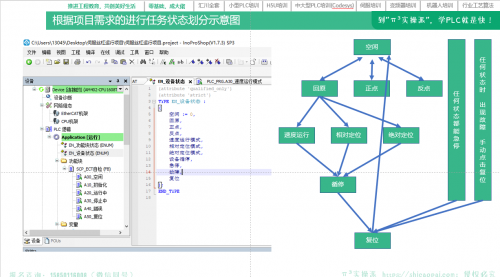

【全科班】汇川中型PLC从0到1就业班(Codesys系统化全科班课程-600节+)-汇川PLC教程

朱子文

共30章节630课时

共30章节630课时

【全科班】汇川技术H5U从0到1就业班(系统化全科班-600节+)

张汉清

共9章节44课时

共9章节44课时

【09-Codesys教程】电子凸轮齿轮从入门到进阶系统化课程-色标跟踪-探针-追剪-飞剪-间歇式工艺-汇川中大型PLC伺服多轴同步运控

朱子文

共5章节63课时

共5章节63课时

【01-Codesys教程】ST文本从0到1,从入门到进阶-汇川中大型PLC教程

朱子文

共6章节52课时

共6章节52课时

【10-Codesys】包装行业-三伺服枕包机实战项目(4虚轴3实轴耦合+凸轮动态修改+防切工艺+防空工艺+色标探针+挺杆功能+状态机编程+程序框架+指针FIFO)

朱子文

PLC16384: Unlocking the Power of Advanced Industrial Automation |

|

1

33

| |

相关帖子

|

|

| |

共31章节616课时

共31章节616课时

【全科班】汇川中型PLC从0到1就业班(Codesys系统化全科班课程-600节+)-汇川PLC教程

朱子文

共9章节44课时

共9章节44课时

【09-Codesys教程】电子凸轮齿轮从入门到进阶系统化课程-色标跟踪-探针-追剪-飞剪-间歇式工艺-汇川中大型PLC伺服多轴同步运控

朱子文

共30章节630课时

共30章节630课时

【全科班】汇川技术H5U从0到1就业班(系统化全科班-600节+)

张汉清

共5章节63课时

共5章节63课时

【01-Codesys教程】ST文本从0到1,从入门到进阶-汇川中大型PLC教程

朱子文

共4章节36课时

共4章节36课时

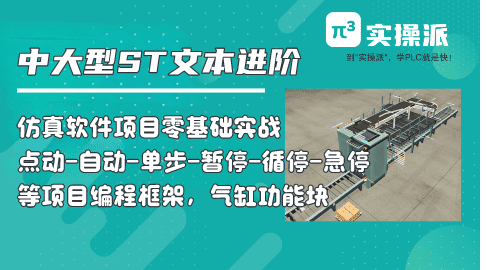

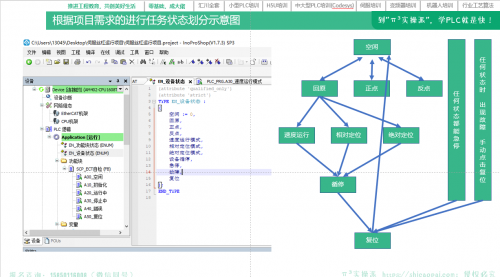

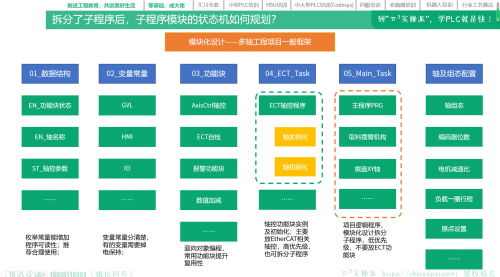

03 中大型ST文本结合仿真软件小项目 31节-气缸功能块封装-状态机编程思路-小设备框架

朱子文

共6章节52课时

共6章节52课时

【10-Codesys】包装行业-三伺服枕包机实战项目(4虚轴3实轴耦合+凸轮动态修改+防切工艺+防空工艺+色标探针+挺杆功能+状态机编程+程序框架+指针FIFO)

朱子文

共4章节29课时

共4章节29课时

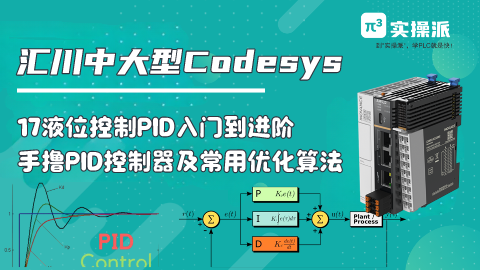

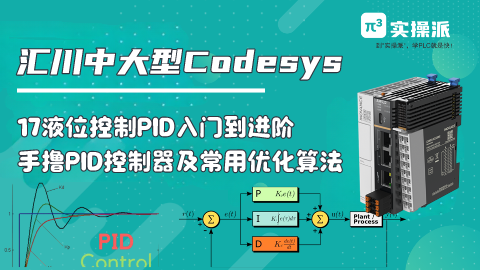

【12-Codesys小课】中大型PLC-PID控制器算法从入门到进阶之液位控制系统

朱子文

共3章节30课时

共3章节30课时

【05-Codesys教程】汇川中大型PLC单轴运动控制教程-汇川PLC教程

朱子文

共3章节25课时

共3章节25课时

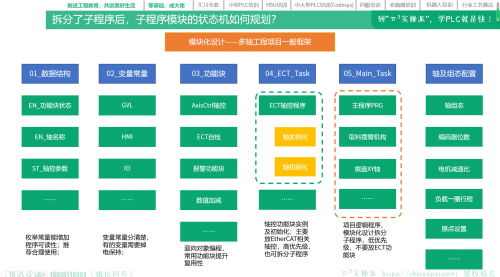

【06-Codesys教程】汇川中大型PLC运动控制进阶篇(多轴PTP)-编程框架与编程模板实操

朱子文

共3章节24课时

共3章节24课时

【08-codesys教程】汇川中大型codesys教程-多轴运控扩展篇经验分享小知识分享

朱子文

金牌会员

1276

主题数

1

粉丝数

0

关注的人

共31章节616课时

共31章节616课时

【全科班】汇川中型PLC从0到1就业班(Codesys系统化全科班课程-600节+)-汇川PLC教程

朱子文

共9章节44课时

共9章节44课时

【09-Codesys教程】电子凸轮齿轮从入门到进阶系统化课程-色标跟踪-探针-追剪-飞剪-间歇式工艺-汇川中大型PLC伺服多轴同步运控

朱子文

共30章节630课时

共30章节630课时

【全科班】汇川技术H5U从0到1就业班(系统化全科班-600节+)

张汉清

共5章节63课时

共5章节63课时

【01-Codesys教程】ST文本从0到1,从入门到进阶-汇川中大型PLC教程

朱子文

共4章节36课时

共4章节36课时

03 中大型ST文本结合仿真软件小项目 31节-气缸功能块封装-状态机编程思路-小设备框架

朱子文

共6章节52课时

共6章节52课时

【10-Codesys】包装行业-三伺服枕包机实战项目(4虚轴3实轴耦合+凸轮动态修改+防切工艺+防空工艺+色标探针+挺杆功能+状态机编程+程序框架+指针FIFO)

朱子文

共4章节29课时

共4章节29课时

【12-Codesys小课】中大型PLC-PID控制器算法从入门到进阶之液位控制系统

朱子文

共3章节30课时

共3章节30课时

【05-Codesys教程】汇川中大型PLC单轴运动控制教程-汇川PLC教程

朱子文

共3章节25课时

共3章节25课时

【06-Codesys教程】汇川中大型PLC运动控制进阶篇(多轴PTP)-编程框架与编程模板实操

朱子文

共3章节24课时

共3章节24课时

【08-codesys教程】汇川中大型codesys教程-多轴运控扩展篇经验分享小知识分享

朱子文

公司地址:江苏省苏州市吴中区越溪街道天鹅荡路5号31B13