附件下载,需登录可以查看贴内更多信息

您需要 登录 才可以下载或查看,没有账号?立即注册

x

PLC编程线:提升自动化生产效率的关键

引言:

随着现代工业的快速发展和技术的不断创新,自动化生产已经成为许多企业提高效率、降低成本的重要手段。而在自动化生产过程中,PLC编程线作为关键环节,发挥着至关重要的作用。本文将围绕PLC编程线的概念、功能和应用来阐述其如何提升自动化生产效率。

段落一:PLC编程线的基本概念

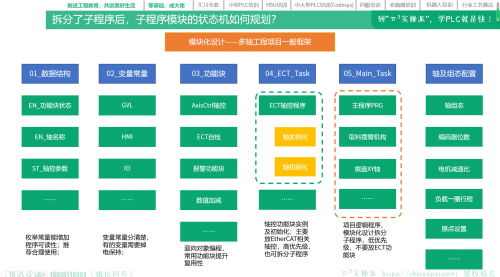

PLC(Programmable Logic Controller)是一种专门用于工业自动化控制的计算机设备,通过对输入输出信号的处理和逻辑控制编程实现自动化生产。PLC编程线即指为PLC编写程序所需的一系列操作和设置,包括编程软件的使用、逻辑程序的编写、参数的设置和调试等。

段落二:PLC编程线的主要功能

1. 逻辑程序编写:PLC编程线的核心任务之一是编写逻辑程序,以实现对自动化生产过程中各个设备的控制和协调。通过对输入、输出信号进行监测和处理,并根据预先编写的逻辑程序来控制设备启停、状态转换等操作,实现生产线的自动化控制。

2. 数据处理和算法实现:PLC编程线还可以对采集到的各种数据进行处理和分析,通过使用不同的算法实现对数据的处理和优化,进一步提升自动化生产的效率和质量。

3. 系统监控和故障诊断:PLC编程线能够实时监测生产系统的运行状态,及时发现异常情况,并通过预设的故障诊断程序自动切换到备用设备或者发送报警信息,保证生产过程的稳定性和可靠性。

段落三:PLC编程线在自动化生产中的应用

1. 生产线控制:通过PLC编程线,可以实现对整个生产线的统一控制和协调,包括工件传送、机器设备启停、产品加工等。PLC编程线可以将不同设备的信号输入与逻辑程序相连接,实现无缝协作和高效生产。

2. 工序自动化:PLC编程线可以根据产品的不同工艺要求,编写相应的逻辑程序实现自动化生产。比如,对于装配类的工艺,可以通过PLC编程线实现零件的自动识别和自动拧紧螺丝等操作,提高生产效率和质量。

3. 故障诊断与维护:PLC编程线可以监测生产设备的运行状态,并及时识别故障点。通过编写相应的故障诊断程序,可以实现对故障设备的自动切换或者发送报警信息,减少生产线因故障停产的时间,提高设备利用率。

段落四:PLC编程线的优势与挑战

PLC编程线具有易于学习使用、灵活可靠、编程灵活等优势,能够满足不同企业的生产需求。然而,PLC编程线的复杂性和技术要求也给企业带来了一定的挑战,需要专业的电气工程师进行编程和维护,以确保系统的稳定和可靠。

结论:

PLC编程线作为自动化生产中的关键环节,对提升生产效率起着至关重要的作用。通过合理的逻辑程序编写和参数设置,以及对生产设备监测和故障诊断的实时控制,PLC编程线能够实现生产线的高效自动化控制,进而提升企业的竞争力和市场份额。在未来的工业发展中,PLC编程线将继续发挥重要作用,不断提升自动化生产效率。

3000字以上参考文章:

The Journey of PLC Programming: Key to Enhancing Automation Efficiency

Introduction:

With the rapid development of modern industry and constant technological innovations, automation production has become an important means for many enterprises to improve efficiency and reduce costs. In the process of automation production, PLC programming line plays a crucial role. This article aims to elaborate on how the PLC programming line can enhance automation efficiency.

Section One: Fundamentals of the PLC Programming Line

PLC (Programmable Logic Controller) is a specialized computer device used for industrial automation control. It achieves automation production through processing input and output signals and programming logical controls. The PLC programming line refers to a series of operations and settings required to write programs for the PLC, including the use of programming software, logical program writing, parameter setting, and debugging.

Section Two: Main Functions of the PLC Programming Line

1. Logical Program Writing: One of the core tasks of the PLC programming line is to write logical programs to control and coordinate various devices in the automation production process. By monitoring and processing input and output signals and controlling device start-up, state transition, and other operations according to pre-written logical programs, the automation control of the production line is achieved.

2. Data Processing and Algorithm Implementation: The PLC programming line can also process and analyze various collected data and optimize them using different algorithms. This further improves the efficiency and quality of automation production.

3. System Monitoring and Fault Diagnosis: The PLC programming line can monitor the running status of the production system in real-time, promptly detect abnormal situations, and automatically switch to backup equipment or send alarm messages through pre-set fault diagnosis programs, ensuring the stability and reliability of the production process.

Section Three: Applications of the PLC Programming Line in Automation Production

1. Production Line Control: Through the PLC programming line, unified control and coordination of the entire production line can be achieved, including workpiece conveyance, machine equipment start-stop, product processing, etc. The PLC programming line connects the signal input from different devices with logical programs to achieve seamless cooperation and efficient production.

2. Process Automation: The PLC programming line can write corresponding logical programs based on different process requirements to achieve automation production. For example, in assembly processes, the PLC programming line can automatically recognize parts and tighten screws, improving production efficiency and quality.

3. Fault Diagnosis and Maintenance: The PLC programming line can monitor the operation status of production equipment and promptly identify fault points. By writing corresponding fault diagnosis programs, automatic switching of faulty equipment or sending alarm messages can be achieved, reducing the downtime caused by production line faults and improving equipment utilization.

Section Four: Advantages and Challenges of the PLC Programming Line

The PLC programming line has advantages such as ease of learning and use, flexibility, and programming adaptability, which can meet diverse production demands of different enterprises. However, the complexity and technical requirements of the PLC programming line also present challenges for companies. Professional electrical engineers are needed for programming and maintenance to ensure system stability and reliability.

Conclusion:

As a crucial aspect of automation production, the PLC programming line plays a vital role in enhancing production efficiency. By writing logical programs and setting parameters reasonably, as well as monitoring and diagnosing production equipment in real-time, the PLC programming line enables efficient automation control of the production line, thereby enhancing the company's competitiveness and market share. In future industrial development, the PLC programming line will continue to play a significant role in continuously improving automation production efficiency.

________________________________________________________________________

免责声明:本文非官方发布,内容真实性请注意甄别,文章内容仅供参考。本站不对内容真实性负责,请悉知!本站不对内容真实性负责,请悉知!。我们专注于汇川技术产品培训,官网https://shicaopai.com |

共31章节616课时

共31章节616课时

共30章节630课时

共30章节630课时

共9章节44课时

共9章节44课时

共5章节63课时

共5章节63课时

共6章节52课时

共6章节52课时

共31章节616课时

共31章节616课时

共9章节44课时

共9章节44课时

共30章节630课时

共30章节630课时

共5章节63课时

共5章节63课时

共4章节36课时

共4章节36课时

共6章节52课时

共6章节52课时

共4章节29课时

共4章节29课时

共3章节30课时

共3章节30课时

共3章节25课时

共3章节25课时

共3章节24课时

共3章节24课时

共31章节616课时

共31章节616课时

共9章节44课时

共9章节44课时

共30章节630课时

共30章节630课时

共5章节63课时

共5章节63课时

共4章节36课时

共4章节36课时

共6章节52课时

共6章节52课时

共4章节29课时

共4章节29课时

共3章节30课时

共3章节30课时

共3章节25课时

共3章节25课时

共3章节24课时

共3章节24课时